Innovation is the key to human progress—without the creation of novel inventions, stagnation would set in, and world-altering breakthroughs would be few and far between. For more than 75 years, Vlier has pushed the envelope on what’s possible in the precision engineering space, building an extensive catalog of more than 3,300 standard parts and a reputation for the manufacturing of high-quality custom products. In 1949, we created our flagship product, the Vlier Pin, which has since perfected many manufacturing lines and products. In honor of National Inventors Month this May, we’re celebrating LMS anti-vibration levelers, another one of our unique creations that have set a standard for shock and vibration solutions.

History and Applications

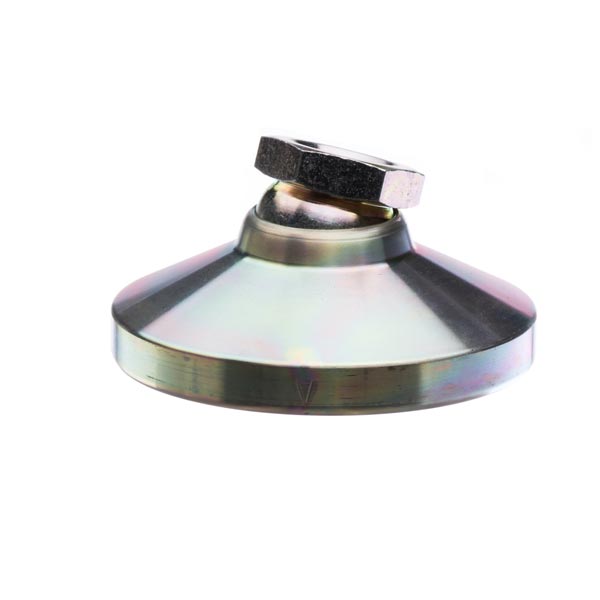

Designed alongside Barry Controls in the late 1990s under a new product development initiative program, the level mount swivel (LMS) anti-vibration leveler is a precision frequency tuned swivel-style leveling device that provides shock attenuation and low-frequency vibration isolation for sensitive equipment.

Introduced to the market for the first time in 1999, Vlier’s LMS anti-vibration levelers are designed for leveling and aligning equipment in a variety of applications, such as:

- Sensitive electronic manufacturing equipment

- Sensitive industrial machines

- Semiconductor equipment

- High precision equipment

Typically, the LMS anti-vibration leveler is used in data storage equipment, large medical equipment, material handling equipment and in industrial environments.

Features and Benefits

The LMS anti-vibration leveler features a steel base that is molded to a .5” black neoprene elastomer to provide maximum control of shock, vibration and noise. The stud style base swivels 15° off the centerline to adjust to uneven surfaces and level machinery. A 3.0” radial ring pad provides a sure grip and non-skid support, while the black-oxide steel studs and nuts resist corrosion. The levelers also have an operating temperature range of -20°F to 180°F (-30°C to 82°C), transmissibility at resonance 8:1, ANSI and metric threads.

When used to level and align equipment, this high-performance isolator:

- Increases machinery performance, precision and throughput

- Extends machinery life by protection from shock and vibration

- Controls machinery creep and movements with its non-skid elastomer

- Protects floors and surface finishes

For more than 20 years, the LMS anti-vibration leveler has proven time and again to be a reliable leveling device that our customers depend on.

Learn More

If you’re interested in how our LMS anti-vibration leveler can aid your manufacturing projects, or if you want to learn more about the many uses of some of our other inventions like the Vlier Pin, reach out to us online today.

Translate

Translate