When it comes to manufacturing, two of the primary goals are ease of assembly and efficiency of use, as perfectly embodied by the installation method of our knurled press-fit plungers. Originally designed as a detent mechanism for indexing shell plates, they have since been adopted across industries including automotive, medical, technology and more. Below, we examine how such a small part can have such a massive impact by reviewing many of the game-changing applications of knurled press-fit plungers.

A Part of History

In the late 1990s, we first developed push-fit plungers, which can be installed without tools—by simply exerting a light force to push them into tight, tolerance holes. Their design includes a resting flange for consistent positioning and allows them to stay securely in place, often without a bonding agent.

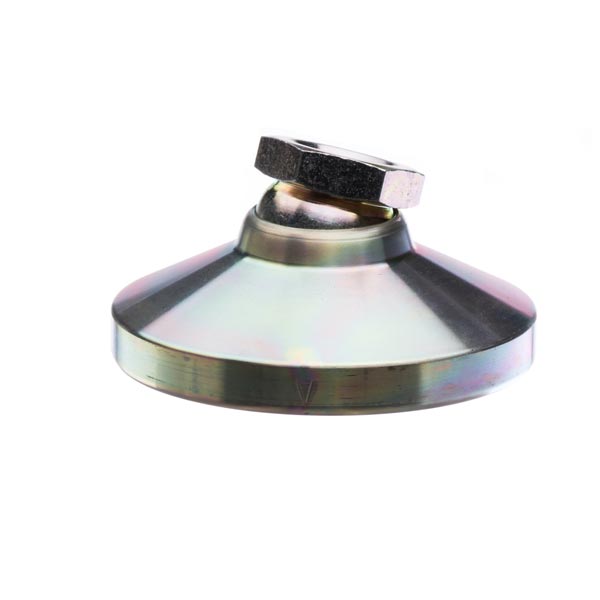

A decade later, we created knurled press-fit plungers, which feature knurled bodies that quickly press into place. This design allows for installation from either end of the plunger into a variety of materials such as wood, plastic, aluminum, steel or stainless steel without the need of a screwdriver or wrench.

The product design also allows manufacturers to automate assembly processes, saving the time-consuming and expensive effort of a threaded installation. A press-fit process is even more effective when installing hundreds or even thousands of plungers.

One Part with Many Applications

While the knurled press-fit plunger was originally designed for a single purpose, it was quickly discovered that the applications are nearly endless. They are ideal components used to position, secure, quick disconnect, index, locate and detent. As new technologies emerge, plungers have been used in robotic surgery arms, automotive, truck, and communications components to assist in the 5G changeover.

These parts provide several benefits over threaded fasteners across all industries, providing improved:

- Speed of installation

- Time and cost savings

- Perfection in plunger location

- Repetition and accuracy

- Increase throughput

Automotive applications:

- Car seating

- Vehicle interiors

- Steering & Braking systems

- Latching devices

- Driveline components

- Switch gear for positioning

- Access panels

Medical applications:

- Orthopedic braces

- Medical Cart mechanisms

- Surgical instruments

- Dental equipment

- Emergency room equipment

- IV dispensing equipment

- LCD position control

How Can We Help?

Knurled press-fit plungers, offered in steel or stainless steel, and available exclusively from Vlier through a trusted global distribution network. Contact us today to learn more about these parts or any other parts in our extensive catalog.

Translate

Translate