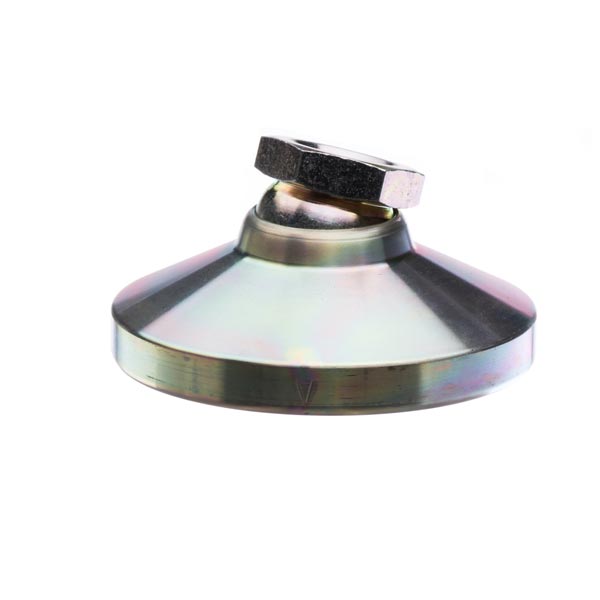

At Vlier Products, we’re never afraid to innovate—eighty years after we first arrived on the scene, we’re still creating new parts made of new materials that open us up to new markets. Our latest innovation is an off-the-shelf line of ceramic ball plungers, which are compact spring loaded devices frequently used in indexing, locating or positioning for a variety of applications. The product design automates and simplifies the assembly process for manufacturers, while the unique ceramic makeup allows engineers to meet the demands of extreme environments. Read on, as we look into how this innovation came to be and how our customers will benefit from the impact of ceramic.

Why Ceramic Plungers?

This undertaking began when we created a solution for an instrument used in spinal surgery for vertebral compression fractures. Our specially designed threaded plunger sets a critical torque value that is needed during the surgical procedure, as to ensure no injuries or damage to bone. At the same time, the hygienic nature of the ceramic ball made it ideal for use within a surgical setting. While this medical application was the catalyst for creating our new line of parts, the other inherent benefits of ceramic opened us up to an array of new industries.

Benefits of using ceramic material include:

- Cleanroom compatibility

- Corrosion resistance

- Electrical insulation

- Easily recyclable

- Longer life than steel/other metals

- Non-magnetic

- Nearly frictionless

- Lower weight than steel

- Non-marking/marring

- High-temperature tolerance

- Enhanced thermal dissipation

The Features of Ceramic

The material we use for our parts, alumina oxide (Al2O3), isan industrial-grade ceramic defined by its high hardness and long-wearing properties. These unique features make alumina oxide ideal for parts that must remain durable under extreme conditions. Here’s a look at alumina oxide by the numbers:

- 2,977: Melting point (°C)

- 2,072: Boiling point (°C)

- 2,000–4,000: Compressive strength (MPa)

- 300–600: Mechanical strength (MPa)

- 15–19: Hardness (GPa)

- 3.95: Density (g/cm3)

The Future Impact

The inclusion of off-the-shelf ceramic products is a giant step forward for Vlier Products, allowing for an exciting expansion of our offerings and industry partnerships. Ournew line of ceramic plungers will help engineers meet specific criteria for temperature tolerance, chemical resistance, longevity and more.

If you are interested in learning more about our capabilities or parts, or if you want to speak with us about your project, we’d love to connect. Reach out today to learn more.

About Vlier

Vlier Products, a unit of Hutchinson Aerospace & Industry, has been an industry leader for more than 80 years manufacturing spring loaded devices, quick-release devices, Vlier Lock Pins, leveling devices and mechanical components. Vlier offers more than 3,300 standard parts in a variety of sizes and materials for aerospace, medical, telecommunications, transportation and more. Every item in their extensive catalog has been engineered to provide the best quality and maximum value in productivity and dependable performance. Working smarter and harder for you, Vlier has the right part for the job. Based out of Massachusetts, Vlier calls upon a global distribution network, making their products readily available worldwide. For more information, visit www.vlier.com.

Vlier Inc.

A unit of Hutchinson Aerospace & Industry

1.800.821.1090

vlier@www.vlier.com

www.vlier.com

ISO:9001 Certified

AS9100 Certified

Cage Code: 01226

Translate

Translate